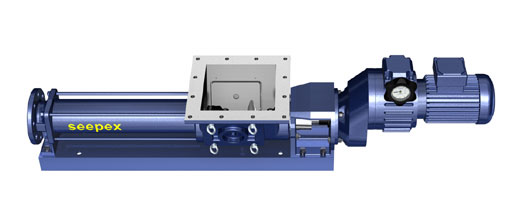

seepex Pumps

seepex T Range Open Hopper Feed Pumps

|

BTQ = seepex pumps of the BTQ range are identical in length to the pumps of range BN and additionally feature a square feed cross-section and an auger feed screw for enhanced product feed. They are used for pumping medium to highly viscous products with a low degree of flowability. BT = seepex pumps of the BT range feature a rectangular feed hopper with compression zone and auger feed screw. The length of the hopper opening is variable to suit the application conditions. They are used for pumping highly viscous media with a low degree of intrinsic flowability. BTE = Features a feed hopper and a compression zone with an enlarged cross-section as well as an auger feed screw with a longer pitch and enlarged diameter. The length of the hopper opening is variable to suit the application conditions. Pumps of this range are used for pumping highly viscous to airtight products that do not tend to bridging. BTI = Pumps of the BTI range feature a rectangular feed hopper with integrated bridge breaker. The compression housing is dismountable for service work. The length of the hopper opening is variable to suit the application conditions. Pumps of this range are used for pumping highly viscous to airtight products that tend to form bridges above the auger feed screw. BTH = The BTH range combines the various advantages of product group T. It is characterized by a separately driven, concentrically rotating ribbon screw with a maximized diameter and a long pitch. Through separate control of the conveying screw speed, the BTH pump can be used for almost any conveying media. The variable speed auger screw permits optimum filling of the conveying elements rotor and stator without causing excess capacity in the stuffing box. Even media that tend to form bridges can be handled with ease due to the large screw diameter of the BTH pump. The BTH range is the technical optimum solution for shear sensitive conveying media. BTHE = Pumps of the BTHE range feature a feed hopper with vertical hopper walls and a ribbon screw rotating centrically and on the edges. This guarantees optimum emptying of the feed hopper and optimised feed of the medium into the conveying elements of the pump. The length of the hopper opening is variable to suit the respective application conditions. BTES = The BTES range is equipped with a shut-off system and Range BTES ensures replacement of the conveying elements with the silo filled BTEI = The BTEI range is a further development of the proven BTI and BTE ranges. In addition to a bridge breaker/mixing device, it features a supply tank that can be adapted to the application conditions on site. This supply tank replaces a separate storage tank and thus saves space within the system. Flows from 50l/hour to 500m3/hour Max pressure up to 48 bar |

seepex pumps of product T Range are used for high-consistency material with low degree of intrinsic flowability or none at all. For these pumping products, the suction lift capability of a standard pump of product group N is no longer sufficient to suck them into pipings. For this reason, pumps of product T Range are equipped with a feed hopper and facilities for safe product feeding. It is successfully used in almost all branches of industry to pump viscous to airtight products.

seepex pumps of product T Range are used for high-consistency material with low degree of intrinsic flowability or none at all. For these pumping products, the suction lift capability of a standard pump of product group N is no longer sufficient to suck them into pipings. For this reason, pumps of product T Range are equipped with a feed hopper and facilities for safe product feeding. It is successfully used in almost all branches of industry to pump viscous to airtight products.