|

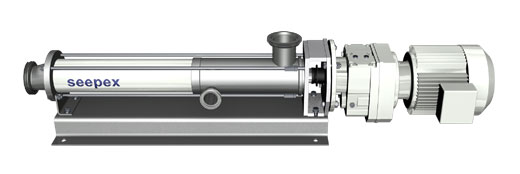

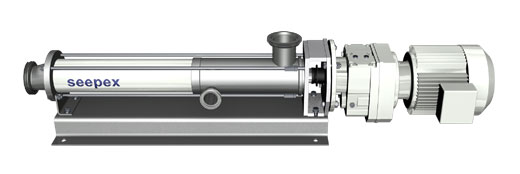

The CS product group of pumps are used primarily in the food, pharmaceutical, cosmetics and chemical industries. “C” stands for CIP (Cleaning in Place) and “S” for SIP-capability (Sterilisation In Place) of the pumps. The CS product group of pumps are used primarily in the food, pharmaceutical, cosmetics and chemical industries. “C” stands for CIP (Cleaning in Place) and “S” for SIP-capability (Sterilisation In Place) of the pumps.

Applications include agriculture, brewing industry and distilleries, chemical and biochemical industry, confectionery industry, dough processing and bakeries, fruit and vegetable processing, milk and dairy industry, pharmaceutical and cosmetics industry, poultry and meat processing and wine industry.

CS Range General Brochure

CS Range General Brochure

All seepex Pump Products Overview

All seepex Pump Products Overview

BCSO = The pumps of the BCSO range are equipped with open hygienic joints that can be cleaned without leaving residues through CIP continuous cleaning. They meet highest demands on hygienic cleanliness and on corrosion and wear resistance. The open fork joint features an especially shaped coupling rod and the rotor or plug-in shaft head. Apart from that, it is made up of only a few components. For higher pressures and conveying capacities, Seepex additionally offers a newly developed, open pin joint. Service work can be performed easily and rapidly without the need for special tools. They are certified acc. to the 3-A Sanitary Standard of the US and designed in compliance with the EHEDG directives.

BCSO Instruction Manual

BCSO Instruction Manual

BCSB = The pumps of the BCSB range differ from those of range BCSO in their joint design. The BCSB range is equipped with the proven, closed pin joints from the Seepex pumps of the BN/NS ranges. These cost-efficient and wear-resistant pin joints are filled with a special grease approved for the food sector and sealed through a resilient universal joint sleeve and holding bands. They are suited for use with abrasive conveying media and high operating pressures.

BCSB Instruction Manual

BCSB Instruction Manual

BTCS = The BTCS range features a feed hopper with a cylindrical/conical compression zone. Highly-viscous conveying media with a low degree of flowability are fed to the conveying elements rotor and stator through the auger feed screw on the coupling rod. Optimum filling of the conveying chamber is achieved through the priming pressure generated in the compression zone. The pumps of the BTCS range are optionally equipped with the open, service-friendly joints or with the proven, closed pin joints.

BTCS Instruction Manual

BTCS Instruction Manual

Flows up to 130 m3/hour

Pressures up to 24 bar

|

The CS product group of pumps are used primarily in the food, pharmaceutical, cosmetics and chemical industries. “C” stands for CIP (Cleaning in Place) and “S” for SIP-capability (Sterilisation In Place) of the pumps.

The CS product group of pumps are used primarily in the food, pharmaceutical, cosmetics and chemical industries. “C” stands for CIP (Cleaning in Place) and “S” for SIP-capability (Sterilisation In Place) of the pumps.