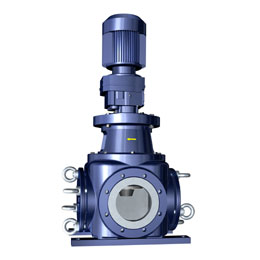

seepex Pumps

seepex CO - Control Systems

|

Advantages and Characteristics

The seepex level control can be used in various control circuits. The basis is a compact programmable logic controller with integrated display and operating unit. The product level is measured through e.g. ultrasonic. The level is controlled via a PID controller that changes the pump speed as a factor of the level. If the PID controller can no longer keep the level constant within the permissible range due to insufficient or excessive product supply or due to a process fault, the controller will trigger appropriate measures. These prevent damage to the system and stop the entire process in an emergency.

seepex offers a solution tailored for processing sewage sludge and pumping highly dewatered sludge from centrifuges or belt filter presses. With this method, the dewatered sludge from the dewatering machine is directly routed into the feed hopper of the seepex pump of the BTI series. At the same time, lime is dosed into the pump hopper via an adjustable screw dosing system and mixed into the sludge by the paddle shaft of the integral bridge breaker. The multi-staged pump then delivers the conditioned sludge to the container, hopper or storage location. To ensure an efficient and trouble-free operation of the overall plant, important process factors must be monitored and controlled, and fault messages must be evaluated. The seepex SLCO control system was developed for this purpose. The SLCO control system has been implemented based on a PLC (programmable logic controller) combined with a visualization system and comprises the following functions.

With an increasing layer of solids on the filter cloths of a filter press, the filtration pressure will rise when the conveying capacity of the feeding pumps stays constant. This causes premature compacting of the layer of solids that is very thin at first, and thus to an unfavourable throughput with accordingly long filtration times. The draining rate (dry matter contents) is also affected. For this reason, premature compacting of the layer of solids must be prevented. This is possible by reducing the delivery rate. The filtration pressure can be used as the process dimension for compacting. Depending on the filtration pressure, the feed rate to the filter press must be reduced appropriately with increasing pressure. A complete filtration cycle is completed when the final pressure that must be set manually has been exceeded. The seepex FPPU controller controls the filter press process as follows:

It is available in the following two variants. Variant FPPU: PLC with integrated LC-display. By use of additional modules this control variant can be extended to the feeding of four filter presses. A bus connection to a master PLC is already included in the software. Storage space is available for max. 20 user-specific characteristic filling curves.

The development of seepex control systems can also be customised under cost-efficient aspects. Let us convince you of our flexibility and rely on our years of experience to meet your demands. After you have contacted us, we will define the control characteristics in a specification sheet together. On this basis, seepex develops your individual solution and creates the control program with the associated documentation. Before the controller is delivered, seepex conducts an in-house final inspection. If desired, we will commission the controller on site. |

seepex control systems are tailored for controlling, regulating and monitoring depending on the respective application.

seepex control systems are tailored for controlling, regulating and monitoring depending on the respective application. Controller For Biogas Plants – BGDC

Controller For Biogas Plants – BGDC Level Control - LVCL

Level Control - LVCL Sludge Conditioning - SLCO

Sludge Conditioning - SLCO Filter Press Feeding - FPPU

Filter Press Feeding - FPPU Customized Solution

Customized Solution