Sotera Systems

1/2" Air Operated

Diaphragm Pumps

1" Air Operated

Diaphragm Pumps

Flow Meters:

Digital Display Meter

Precision Aluminum

Flow Meters

Sotera Digital Register - Aluminum Meter: Fuel Sentry Systems

|

Fill-Rite offers full system solutions for monitoring Power and Energy usage though the sophisticated management of incoming and outgoing fuel consumption. The system is based on two TM Series meters combined with a rugged two-channel electronic totalizer.The Fuel Sentry package can be expanded with temperature compensation on one or both flow meters. With this powerful capability is it possible to track usage, waste, illegal fuel usage, un-spent fuel, and system inefficiencies in boilers, diesel engines, and other fuel consuming industrial equipment. With the Fuel Sentry Systems it is possible to integrate weights and measure metering into fuel control systems that improve visibility into total system operations. The Fuel Sentry Fuel system offers the ability to track fuel usage, fuel consumption, and enhance fuel system automation. By placing a meter on the input and on the output side of the system it is possible to monitor the actual fuel usage as well as the unspent fuel that is re-circulated. Diesel Engine Fuel Consumption The Fuel Sentry System helps identify any potential waste, theft, engine inefficiencies (same output, more fuel usage), as well as ability to control flows through additional dosing and metering capabilities. Diesel engines tend to have oversized fuel pump lines meaning tracking the fluid flow into a system is not a good indicator of actual fuel consumption. In some instances 50-70% of the unspent fuel returns through the Recirculation lines for re-use. In instances where the return fuel line has been heated (expansion of fuel), it then becomes necessary to properly monitor the temperature so accurate consumption and reporting can be made; especially important when an EPA regulatory emission report is required. Boilers and Heaters Fuel Consumption The Fuel Sentry System helps identify fuel usage, potential waste, theft, boiler inefficiencies (same output, more fuel usage), as well as ability to control flows through additional dosing and metering options. Boilers and heaters tend to have more closely aligned fuel input and fuel consumption with approximately 10% of the unspent fuel returned through the Recirculation lines. In instances where the return fuel line has been heated (expansion of fuel), it then becomes necessary to properly monitor the temperature so accurate consumption and reporting can be made; especially important when an EPA regulatory emission report is required.

Features & Benefits

|

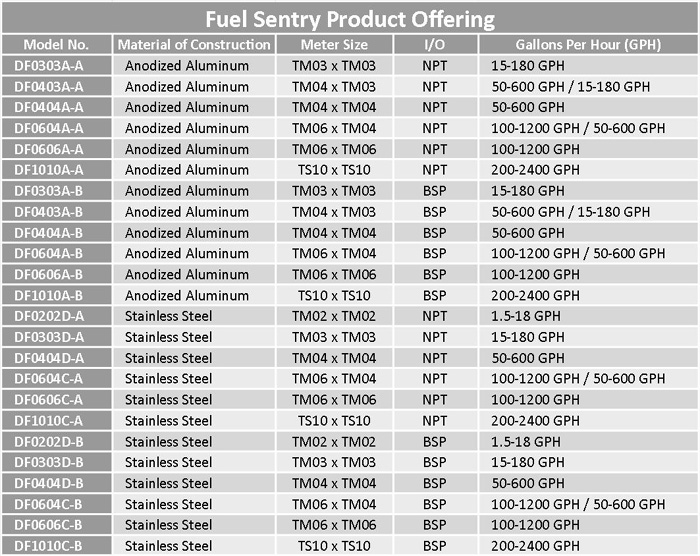

Fuel Sentry Systems

Fuel Sentry Systems