Chemical Process Equipment From Kenco Engineering

USA Toll Free: 1-800-730-0302 Tel: 416-240-1920 - sales@metexcorporation.com

Search This Site

(Search by Product Type i.e. Level or Brand Name i.e. Walchem)

|

Chemical Process Equipment Precise and Accurate Solutions for Monitoring the Performance of Chemical Injection Systems |

|

DDC Calibration Cylinders

<< Learn More >> |

|

30000 Series Pump Setting Gauge The stay rod type pump setting gauges are used to calibrate the flow rate of chemical metering pumps and chemical injection systems. They are also used to periodically monitor the performance and accuracy of a chemical injection system. It can also be used as the primary containment reservoir of a fluid that will be pumped into a chemical injection system. << Learn More >> |

|

7000 Series Injection Rate Gauge The 7000 Injection Rate Gauge is of the same construction as the 5700 gauge but is provided with a spring-loaded test valve similar to the valve supplied on the 779 Drum Gauge. The test valve is used to isolate the chemical supply tank from the gauge to conduct a one minute calibration test for the chemical pump. << Learn More >> |

|

929 Series Pump Setting Gauge The 929 Series Pump Setting Gauge provides a means for checking the pumping rate of any chemical pump under actual pumping conditions in one minute. The gauge mounts in the pump's suction line between the reservoir tank and the pump. It provides a visual gauge showing the liquid level in the reservoir in addition to a rapid means for setting the pump. << Learn More >> |

|

Drum Gauges KENCO aluminum drum gauges are an important part of a chemical injection skid. Drum Gauges are used to measure the liquid level inventory in horizontal 55 gallon chemical storage tanks. In addition, several models come complete with a test valve to set the injection rate of a chemical metering pump. << Learn More >> |

|

Chemical Injectors KENCO Chemical Injectors are designed to inject and properly atomize corrosive chemicals into the turbulent stream of a process system pipeline. The KENCO Chemical Injector will minimize the possibility of corrosive chemical build-up on the walls of the pipeline. << Learn More >> |

|

Calibration Pots Calibration Pots provide the means for determining chemical pump flow rates. The gauge is installed between the suction side of the chemical pump and the tank. the pump rate is checked by closing the valve between the tank and gauge and observing the level change in the gauge for one minute. << Learn More >> |

|

AccuRate® Pump Setting Gauges The KENCO AccuRate® Pump Setting Gauges utilize precision scientific glass to provide the most accurate reading possible for calibrating the flow rate of a chemical metering pump. They are also used to periodically monitor the performance and accuracy of a chemical injection system. Additionally, the AccuRate® gauge can be used as the primary containment reservoir of a fluid that will be pumped into a chemical injection system. << Learn More >> |

|

5700 Injection Rate Gauge The Model KMD is an advanced, state-of-the-art, two-wire, Magnetostrictive-based level transmitter suitable for a wide range of process applications. The latest microprocessor technology allows this instrument to consistently and reliably measure the level of your process fluid. Built-in Hart® Communications allows for remote calibration and diagnostics. The optional onboard display and keypad is for local display and calibration. << Learn More >> |

|

17000 Injection Rate Gauge The 17000 Gauge functions as an injection rate gauge and also serves a bulk tank level gauge. The rate scale can be calibrated in a variety of options, such as GPM, GPH, GPD, LPM, LPH, or LPD. The maximum pump rate for a 12" gauge section is 25 GPD. The sight tube in the 17000 is 1" O.D. glass, which makes it ideal for viscous fluids. The top and bottom connection for this gauge are 1" MNPT. << Learn More >> |

|

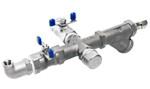

KMK Injection Rate Gauge Manifold The Patented KENCO Manifold Kit simplifies the installation of a metering pump and a KENCO Calibration Gauge to a chemical storage tank. The Manifold’s integral ball valve and strainer minimizes assembly, leak paths and installation time. The butterfly handles on the ball valves allow the manifold size to be very compact. << Learn More >> |

|

Product Range PDF Files |