|

Diaphragm Valves that make a big difference Diaphragm Valves that make a big difference

Diaphragm valves are not normally a major consideration, but RoboValves will change your mind. Designing your process with RoboValves will improve your performance in down-stream processes, such as filtration or chromatography and in many other situations where you are handling valuable products.

RoboValve will save process time and minimize the number of valves and diaphragms, thus reducing costs.

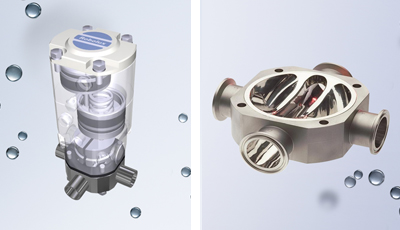

The secret is NO hold-up volumes!!! This is achieved by allowing two valves, independently actuated, mounted under a single diaphragm, saving space and eliminating T-pieces. Innovation is rarely this radical, design rarely makes such a difference.

Burkert Biotech GmbH acquired the assets of Robolux AB in 2005. Through our strategy and brand mainly in conjunction with our Higienic Processing Segment we offer our customers a truly comprehensive systems package within the Pharma and Bio Pharm industries.

The Robolux valve (Robovalve) was invented in the early 1990´s in direct response to industry demands to minimize the system volume and dead legs inside Bio Process units. The "two-shut-off one diaphragm one actuator" - technology is patented and truly a unique solution; Robolux valves are installed in Biopharmaceutical companies all around the world. Even though designing flow paths with multi-way multi-port valves does require a little extra thinking at the beginning you can be sure that the final result will always be worth the effort. When combining Robolux technology with the Process Valves and Block Valves we are able to offer Diaphragm Valve users the best possible solution.

|